Nylon

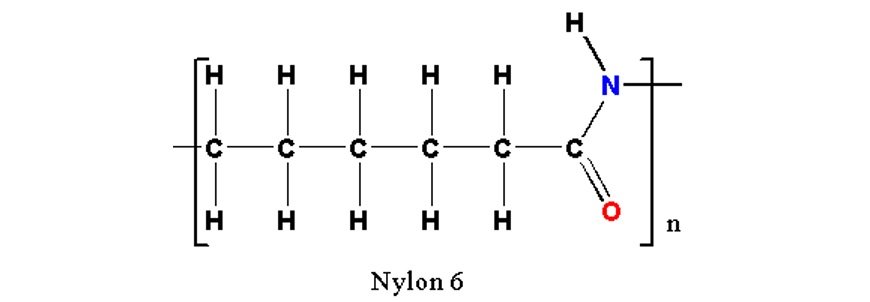

Structure

- Condensation polymer derived from condensation reaction of monomers containing terminal carboxylic acid and amine groups.

- The monomers form repeating units and alternate in the chain.

Reference image for structure

Properties

- Strong, elastic and easy to wash.

- Have the ability to retain shape even after heavy strain.

- Possesses excellent abrasion resistance and colour lightfastness.

- High resistance to insects, fungi, animals, as well as molds, mildew, rot and many chemicals.

Uses

- In manufacture of parachutes.

- Common material for production of different forms of clothing, fabrics and ropes.

- Nylon resins are used in automobile and food industries.

Polyesters

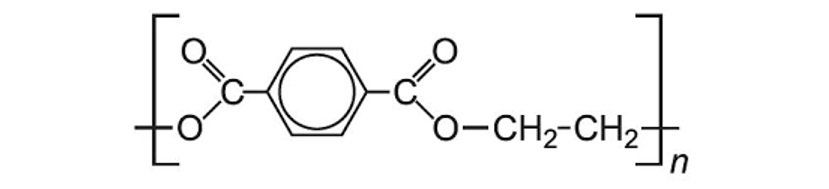

Structure

- Polymers formed from a dicarboxylic acid and a diol, also known as Polyethylene Terephthalate.

- Being an ester, it is made from an acid, benzene-1,4-dicarboxylic acid (terephthalic acid), and an alcohol, ethane-1,2-diol.

- Each repeating unit of monomer is held with an ester linkage.

Reference Image for structure:

Properties

- Formation of highly effective Van der walls force and hydrogen bonds provide good tenacity.

- The hydrophobic nature of the polymer system attracts fats, oils, grease, acids etc.

- Poor heat conductor and resistant to UV radiation from the sun.

Uses

- Fabrics woven from polyester are used in apparel and home furnishing.

- Industrial polyester fibers, yarns and ropes are used in car tire reinforcements, fabrics for conveyor belts, safety belts, coated fabrics and plastic reinforcements with high-energy absorption.

- Polyesters are also used to make bottles, films, tarpaulin, canoes, liquid crystal displays, holograms, filters, dielectric film for capacitors, film insulation for wire and insulating tapes.

Reference: