Production of Materials > 2. Biomass Research >

Use available evidence to gather and present data from secondary sources and analyse progress in the recent development and use of a named biopolymer. This analysis should name the specific enzyme(s) used or organism used to synthesise the material and an evaluation of the use or potential use of the polymer produced related to its properties

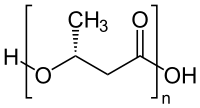

- Polyhydroxylalkanoates (PHAs): biopolymers, produced by microorganisms, that have very similar properties to polypropylene.

- Importantly, PHAs are biodegradable.

- The simplest and most common PHA is polyhydroxylbutanoate (PHB).

- PHB has quite a different chemical structure from polypropylene, although its physical and mechanical properties are quite similar.

- To produce PHB:

- A culture of microorganisms, such as Alcalingenes eutrophus, is placed in a suitable medium and fed appropriate nutrients so that it multiplies rapidly and grows into a large quantity.

- The main nutrient required is glucose, which is a renewable resource.

- The ‘diet’ of the organism is changed to restrict the supply of one particular nutrient, such as nitrogen.

- Under these conditions, the organism is no longer able to increase its population but instead begins to make the desired polymer, which it stores for later use as an energy source.

- The organism can produce a quantity of PHB from 30% to 80% of its own dry weight.

- The organism is harvested and the polymer separated out.

- PHB is stable to air and moisture, but under anaerobic conditions it is attacked and decomposed by anaerobic bacteria.

- PHB, and PHAs generally, are still in the early stages of large-scale production and use.

- They have great potential where biodegradability is a prime consideration, such as in:

- Disposable nappies.

- Packaging, in the form of bottles, bags and wrapping film.